This option allows you to import unit properties, resource contents, or user settings from a WLP file to an object of the appropriate type. It makes sense only if you already have any WLP files.

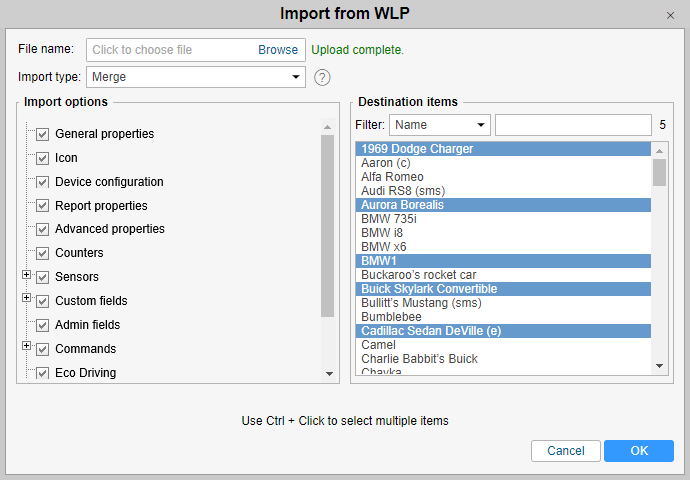

Choose a file and press Upload. Afterwards, the chosen file is processed on the server, and available contents are displayed in the Import options section. At the same time, objects of a proper type are displayed in the section on the right (Destination items).

This list is filtered by units of measure since it is not possible to import data if the source and destination items have different systems of measurement. For more information see the Measurement system and conversion section.

If the file contains the properties of the unit, the list of found properties is displayed to the left, and the list of available units is displayed to the right. If the file contains data from the resource, the list of found elements is displayed to the left, and the list of available resources is displayed to the right. If the file contains user settings, the list of these settings is displayed to the left, and the list of available users is displayed to the right.

On the left, select the data to import, and on the right — the destination objects. Use the dynamic filter to quickly find a necessary object (works by various criteria).

For unit properties (such as sensors, custom fields, commands, service intervals) and resource contents you should also choose import type.

Replace. Data will be replaced completely.

Merge. Items with the same name will be replaced and the new items will be added.

Append. Items with the same name will be left intact and the new ones will be added.

Regardless of the selected type of import, the Replace type is always used when importing the eco driving criteria, that is, the old data is deleted and the new one is entered.

At the end, click OK. If all or some of the data was not imported, a warning message is displayed on the screen. It contains a link to a file which you can download to see what data was imported and what was not. You can also check the status of the operation in the log.