Engine hours

The Engine hours table shows how long the unit worked, how much time was in motion, how much fuel was spent for this period. Also, the duration and efficiency of the work of the attachable equipment can be shown.

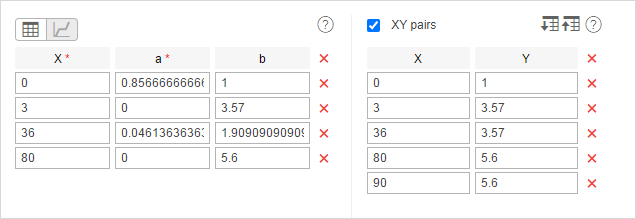

To generate a report using the Engine hours table, the unit is supposed to have such sensors as ignition or absolute/relative engine hours sensor. The method of calculating engine hours is set in unit properties on the General tab. On the Advanced tab, you can also set Daily engine hours rate to calculate utilization and productivity.

In the Engine hours sensor section in the table settings, you can specify the mask for the main engine hours sensor that is used in the report. This allows you to separate the engines and create a table for each of them.

There are two options that can be used in the Engine hours table. They are timeout (set for a sensor) and maximum interval between messages (set for a unit). Both options are used to cut off invalid intervals when the amount of engine hours is defined. If values for both timeout and maximum interval between messages are indicated, the system will use the property with the minimum value indicated.

The Engine hours table can include the columns described below.

| Column | Description |

|---|---|

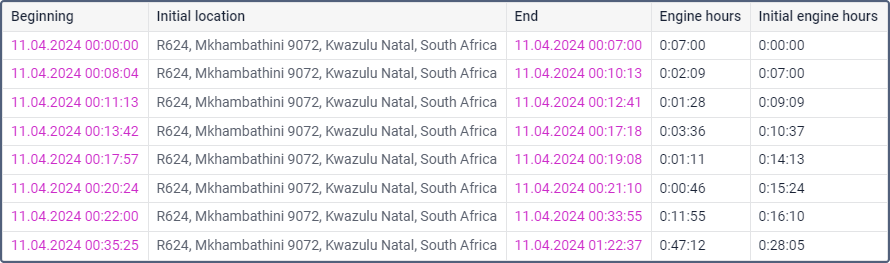

| Beginning | The time when the engine hours interval begins. |

| Initial location | The location of the unit when the engine or implement starts working. |

| End | The time when the engine hours interval ends. |

| Final location | The location of the unit when the engine or implement ends working. |

| Engine hours | The value of engine hours at the interval. For an accurate calculation of engine hours, the device should send a valid value of the selected sensor. In case of receiving an invalid value, it is necessary to replace the sensor with a validator using the correct value. |

| Initial engine hours | The value of the Absolute engine hours sensor at the start of the engine hours interval. If there are no values of this sensor within the interval for which the report is being executed, the initial value of the engine hours is calculated using the counter from the beginning of the interval to the first engine hour interval. In this case, the hour count starts from 0. If the sensor has sent a message with data not included in the scope of the engine hour interval, but included in the interval for which the entire report is being executed, the engine hour value is calculated by the counter with consideration of the absolute engine hour sensor data. |

| Final engine hours | The value of the sensor Absolute engine hours at the end of the interval. Calculated based on the initial engine hours. |

| Total time | The time from the start to the end of engine hours interval. It is recommended to use this column in combination with the grouping parameter or the Total row. If the Total row is configured in the table, it shows all the time that elapsed from the start of the first engine hours interval to the end of the last one. |

| Off-time | The period of time passed from the end of the previous interval to the beginning of the current one (determined starting from the second interval). |

| In motion | The interval of time during which the unit moved, that is, the speed value was greater or equal to the one from the Min moving speed field in the trip detector. |

| Idling | The time when the unit was standing with the engine on. Note that idling cannot be detected if the equipment does not send messages containing speed value. |

| Mileage | The distance traveled during the operating hours. |

| Mileage (adjusted) | Mileage subject to the coefficient set in the unit properties (the Advanced tab). |

| Initial mileage | The value of the mileage sensor at the moment of the beginning of the reporting period. |

| Final mileage | The value of the mileage sensor at the end of the reporting period. |

| Avg. speed | The average speed during the interval of engine operation. See how the average speed is calculated on the Data in reports page. |

| Max. speed | The maximum speed during the interval of engine operation. |

| Counter | The counter sensor value. |

| Initial counter | The counter value at the beginning of the interval. |

| Final counter | The counter value at the end of the interval. |

| Avg. engine revs | The average rate of engine revolutions. |

| Max. engine revs | The maximum rate of engine revolutions. |

| Avg. temperature | The average temperature value registered for the interval of engine operation. |

| Min. temperature | The minimum temperature value registered for the interval of engine operation. |

| Max. temperature | The maximum temperature value registered for the interval of engine operation. |

| Initial temperature | The temperature value at the beginning of the engine hours operation. |

| Final temperature | The temperature value at the end of engine hours operation. |

| Status | The unit status registered during the engine hour interval. It can be registered manually or automatically by means of a notification. If there are several registered statuses, the first of them is displayed. |

| Cargo weight | The average value of cargo weight during the engine hours interval. |

| Driver | The name of the driver (if assigned). |

| Trailer | The name of the trailer (if assigned). |

| Movement productivity | The percentage ratio of engine hours in the movement to the duration of engine hours. |

| Engine efficiency duration | The duration of the operation of attached equipment (if there is the engine efficiency sensor). |

| Engine efficiency idling | The engine operation time after deduction of efficiency time (total engine hours subtract engine efficiency duration). |

| Utilization | The percentage ratio of the duration of engine hours to engine hours rate (engine hours divided by daily engine hours rate indicated in the unit properties in the Advanced tab). |

| Useful utilization | The percentage ratio of the duration of engine efficiency to the engine hours rate. |

| Productivity | The percentage ratio of the duration of engine efficiency to the duration of engine hours. |

| Fuel consumed | The volume of fuel consumed during the engine hour interval and detected by any sort of fuel sensor. If several sensors are available, their values sum up. |

| Consumed by ImpFCS | The fuel volume detected by an impulse fuel consumption sensor. |

| Consumed by AbsFCS | The fuel volume detected by an absolute fuel consumption sensor. |

| Consumed by InsFCS | The fuel volume detected by an instant fuel consumption sensor. |

| Consumed by FLS | The fuel volume detected by a fuel level sensor. |

| Consumed by math | The fuel volume calculated by math. |

| Consumed by math for FLS | The fuel volume calculated by math based on the data from a fuel level sensor (FLS). |

| Consumed by rates | The fuel volume calculated by rates. |

| Energy consumed | The amount of battery energy in kWh consumed during the engine hours interval. It is calculated using the readings of the battery level sensor. |

| Avg. fuel consumption | The average fuel consumption by all available fuel sensors. It’s calculated by dividing the Fuel consumed value by the number of engine hours in the interval. |

| Avg. consumption by ImpFCS | The average fuel consumption detected by an impulse fuel consumption sensor. |

| Avg. consumption by AbsFCS | The average fuel consumption detected by an absolute fuel consumption sensor. |

| Avg. consumption by InsFCS | The average fuel consumption detected by an instant fuel consumption sensor. |

| Avg. consumption by FLS | The average fuel consumption detected by a fuel level sensor. |

| Avg. consumption by math | The average fuel consumption calculated by math. |

| Avg. consumption by math for FLS | The average fuel consumption calculated by math based on the data from a fuel level sensor (FLS). |

| Avg. consumption by rates | The average fuel consumption calculated by rates. |

| Avg. energy consumption | The average battery consumption in kWh/h during the engine hours interval. It is calculated using the readings of the battery level sensor. |

| Consumed by ImpFCS in motion | The fuel volume used in engine hours while moving, detected by an impulse fuel consumption sensor. |

| Consumed by AbsFCS in motion | The fuel volume used in engine hours while moving, detected by an absolute fuel consumption sensor. |

| Consumed by InsFCS in motion | The fuel volume used in engine hours while moving, detected by an instant fuel consumption sensor. |

| Consumed by FLS in motion | The fuel volume used in engine hours while moving, detected by a fuel level sensor. |

| Consumed by math in motion | The fuel volume used in engine hours while moving, calculated by the math. |

| Consumed by math in motion for FLS | The fuel volume used in engine hours while moving, calculated by math based on the data from a fuel level sensor (FLS). |

| Consumed by rates in motion | The fuel volume used in engine hours while moving, calculated by rates. |

| Energy consumed in motion | The amount of battery energy in kWh consumed during the engine hours interval while the unit was moving. |

| Avg. consumption by ImpFCS in motion | The average fuel consumption in engine hours while moving, detected by an impulse fuel consumption sensor. |

| Avg. consumption by AbsFCS in motion | The average fuel consumption in engine hours while moving, detected by an absolute fuel consumption sensor. |

| Avg. consumption by InsFCS in motion | The average fuel consumption in engine hours while moving, detected by an instant fuel consumption sensor. |

| Avg. consumption by FLS in motion | The average fuel consumption in engine hours while moving, detected by a fuel level sensor. |

| Avg. consumption by math in motion | The average fuel consumption in engine hours while moving, calculated by math. |

| Avg. consumption by math in motion for FLS | The average fuel consumption in engine hours while moving, calculated by math based on the data from a fuel level sensor (FLS). |

| Avg. consumption by rates in motion | The average fuel consumption in engine hours while moving, calculated by rates. |

| Avg. energy consumption in motion | The average battery consumption in kWh/h during the engine hours interval while the unit was moving. |

| Consumed by ImpFCS in idle run | The fuel volume used in engine hours during idle running, detected by an impulse fuel consumption sensor. |

| Consumed by AbsFCS in idle run | The fuel volume used in engine hours during idle running, detected by an absolute fuel consumption sensor. |

| Consumed by InsFCS in idle run | The fuel volume used in engine hours during idle running, detected by an instant fuel consumption sensor. |

| Consumed by FLS in idle run | The fuel volume used in engine hours during idle running, detected by a fuel level sensor. |

| Consumed by math in idle run | The fuel volume used in engine hours during idle running, calculated by math. |

| Consumed by math for FLS in idle run | The fuel volume used in engine hours during idle running, calculated by math based on the data from a fuel level sensor (FLS). |

| Consumed by rates in idle run | The fuel volume used in engine hours during idle running, calculated by rates. |

| Energy consumed in idle run | The amount of battery energy in kWh consumed during the engine hours interval while the unit was parked with the ignition on. |

| Avg. consumption by ImpFCS in idle run | The average fuel consumption in idling, detected by an impulse fuel consumption sensor. |

| Avg. consumption by AbsFCS in idle run | The average fuel consumption in idling, detected by an absolute fuel consumption sensor. |

| Avg. consumption by InsFCS in idle run | The average fuel consumption in idling, detected by an instant fuel consumption sensor. |

| Avg. consumption by FLS in idle run | The average fuel consumption in idling, detected by a fuel level sensor. |

| Avg. consumption by math in idle run | The average fuel consumption in idling, calculated by math. |

| Avg. consumption by math for FLS in idle run | The average fuel consumption in idling, calculated by math based on the data from a fuel level sensor (FLS). |

| Avg. consumption by rates in idle run | The average fuel consumption in idling, calculated by rates. |

| Avg. energy consumption in idle run | The average battery consumption in kWh/h during the engine hours interval while the unit was parked with the ignition on. |

| Avg. consumption by ImpFCS in trips | The average fuel consumption in trips, detected by an impulse fuel consumption sensor. |

| Avg. consumption by AbsFCS in trips | The average fuel consumption in trips, detected by an absolute fuel consumption sensor. |

| Avg. consumption by InsFCS in trips | The average fuel consumption in trips, detected by an instant fuel consumption sensor. |

| Avg. consumption by FLS in trips | The average fuel consumption in trips, detected by a fuel level sensor. |

| Avg. consumption by math in trips | The average fuel consumption in trips, calculated by math consumption. |

| Avg. consumption by math for FLS in trips | The average fuel consumption in trips, calculated by math based on the data from a fuel level sensor (FLS). |

| Avg. consumption by rates in trips | The average fuel consumption in trips, calculated by rates. |

| Avg. energy consumption in trips | The average battery consumption in kWh per 100 km or mi during the engine hours interval while the unit was on a trip. |

| Initial fuel level | The fuel level at the beginning of the interval. |

| Final fuel level | The fuel level at the end of the interval. |

| Max. fuel level | The maximum fuel level during the engine hours interval. |

| Min. fuel level | The minimum fuel level during the engine hours interval. |

| Initial battery level | The battery level in kWh at the beginning of the engine hours interval. |

| Final battery level | The battery level in kWh at the end of the engine hours interval. |

| Max. battery level | The maximum battery level during the engine hours interval. |

| Min. battery level | The minimum battery level during the engine hours interval. |

| Penalties | The penalties calculated for the adjusted Eco driving criteria. Penalty averaging for grouping rows (group headings) can be adjusted in report settings. |

| Rank | The received penalty points converted into a grade using a 10-point scoring system. |

| Avg. value of custom sensor | The average value of a custom sensor during the engine hours interval. This and the following columns of custom sensor values show a dash if the sensor parameter has a text value or the value is invalid. For example, if the value is not within the acceptable range. |

| Min. value of custom sensor | The minimum value of a custom sensor during the engine hours interval. |

| Max. value of custom sensor | The maximum value of a custom sensor during the engine hours interval. |

| Initial value of custom sensor | The initial value of a custom sensor at the beginning of the engine hours interval. |

| Final value of custom sensor | The final value of a custom sensor at the end of the engine hours interval. |

| Notes | An empty column for your custom comments. |

For the Engine hours table, you can apply interval filtering by engine hours sensor, duration, mileage, engine hours, speed range, trips, stops, parkings, sensors, sensors masks, driver, trailer, fuel fillings, fuel drains, battery charges, and geofences/units. If the engine hours are counted according to the engine hours sensor, it is possible to filter the intervals not only by the duration of their operation (that is the duration of their on-state), but also by the value of the engine hours sent by the sensor itself.