Additional settings of fuel level sensors

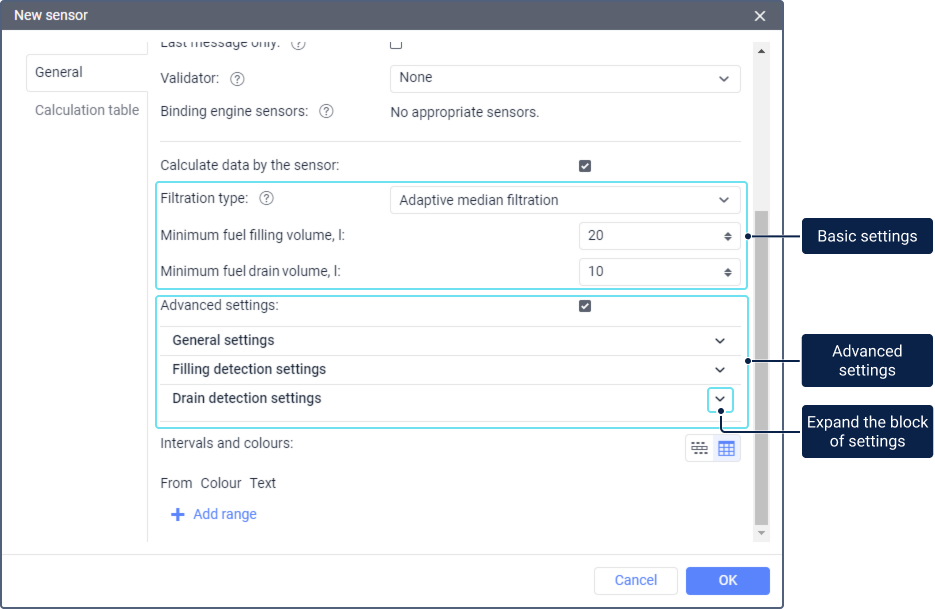

The fuel level sensor (FLS) has additional settings which are shown when the Calculate data by the sensor option is activated. These settings are divided into basic and advanced ones.

Calculate data by the sensor

The Calculate data by the sensor option allows the system to include or exclude the data calculated by the fuel level sensor. For example, you can disable the option if you are temporarily not using the sensor but don’t want to delete it.

If the option is enabled, the data calculated by the sensor is taken into account in reports, notifications, Dashboard, unit tooltips, and in the work list. In Wialon for Android/iOS the enabled option allows to see fuel level data in the unit section.

If the option is disabled, the system no longer takes the sensor data into account, and notifications about fuel fillings and drains based on this sensor stop working.

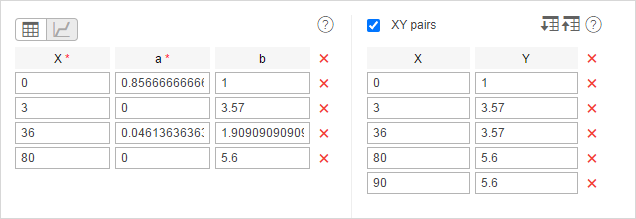

When using this sensor, the fuel consumption is calculated on the basis of the fuel level in the tank according to the following formula:

[fuel level value at the beginning of the interval] − [value at the end of the interval] + [fillings] − [drains]

Drains are subtracted if the Exclude drains from fuel consumption option is activated.

Different report tables have different intervals. For more information about the intervals, see the description of the tables.

Basic settings

The basic settings of the fuel level sensor include three options.

Filtering type

This option allows smoothing the sensor values to avoid data outliers (sudden changes in the fuel level: rises or falls).

Filtering of FLS values is taken into account in reports (in tables and charts when displaying smoothed lines), in jobs for sending fuel level information, and in notifications about fuel fillings and drains.

The drop-down list contains three items:

| Item | Description |

|---|---|

| None | Select this item if the data doesn’t require filtering. |

| Median filtering | If you select median filtering, you should specify its level, that is, how much the data should be smoothed. For information about this type of filtering and the selection of a suitable filtering level, see Median filtering of FLS values. |

| Adaptive median filtering | If you select adaptive median filtering, no additional settings are required. The algorithm automatically selects a suitable value based on the unit data. The algorithm smoothes small random fluctuations in fuel level without affecting significant variations. This allows detecting fuel fillings and potential drains more efficiently and determining their volume more accurately. |

The unit tooltip and the extended unit information show raw FLS values, that is, the values which haven’t been filtered yet.

Minimum fuel drain volume

The minimum decrease in the fuel level which should be considered a drain. The value of this field should be greater than 0 and can be fractional.

Minimum fuel filling volume

The minimum increase in the fuel level which should be considered a filling. The value of this field should be greater than 0 and can be fractional.

Advanced settings

The system uses default values for the advanced settings, but you can change them if needed. To do this, activate the Advanced settings option and edit the values in the General settings, Filling detection settings, and Drain detection settings blocks. If the Advanced settings option is deactivated, the edited values are replaced by the default ones.

General settings

Calculate fuel consumption by time

If this option is enabled, all time intervals, regardless of whether the unit has been moving or not, are included in the calculation of fuel consumption. If this option is disabled, the fuel level on the intervals without movement is not included in the calculation.

For the time-based fuel calculation, you should activate the Calculate fillings by time, Calculate drains by time, and Calculate fuel consumption by time options at the same time.

Replace invalid values with those calculated mathematically

If this option is enabled and the system detects negative values of consumed fuel volume, they are replaced with the following values:

- mathematucally calculated ones, if a mathematical model is created;

- 0, if there is no mathematical model.

To create a basic mathematical model, you should just fill in the fields in the math consumption wizard. For a more accurate model, it is required to configure an ignition sensor, sensors of relative and absolute engine hours, and an engine efficiency sensor. For further information, see the expert article on math consumption.

The option only affects the data of the Fuel consumed and Avg. fuel consumption columns in reports.

Ignore the messages after the start of motion

This option allows skipping messages during the indicated number of seconds at the beginning of movement when determining the fuel level. Otherwise, you can get inaccurate data due to various factors. The start of the movement is registered when the minimum speed indicated in the trip detector is reached.

Exclude drains from fuel consumption

This option can be useful if you want to ignore drains when calculating fuel consumption in different tables and statistics. By default drains are considered a part of fuel consumption. If the option is enabled, columns such as Consumed by FLS, Average consumption by FLS, Consumed by FLS in idle run, Average consumption by FLS in idle run, and similar, are calculated without considering fuel drains. See the full list of columns and tables below.

Filling detection settings

Calculate fillings by time

This calculation method is recommended for units with high fuel consumption at idling (generator, tower crane, etc.). When this option is activated, all time intervals are included, regardless of trips/stops.

Detect fuel fillings only during stops

When this option is enabled, fillings are detected only at stops, that is, when the speed of the unit is lower than the minimum one indicated in the trip detection. This allows reducing the number of false fillings which are caused, for example, by fluctuations in the fuel level during movement.

The initial fuel level is taken from the first message without movement or from the last message with movement.

If any value is indicated in the Timeout to detect final filling volume field, the fillings are also detected during this time after the stop ends.

If a time period between stops is less than the one indicated in the Timeout to separate consecutive fillings field, such stops and the movement intervals between them are considered as one stop. The time when the first stop begins is considered to be the beginning of the filling, and the time after the last stop and the expiration of the timeout is considered to be the end of the filling.

Timeout to detect final filling volume

This field becomes available when the previous option is activated. Here you can indicate the duration of interruptions between fuel entries in the process of filling. To determine the fuel level after the filling, the message that follows the indicated timeout is used, but not the last one that corresponds to the filling. To determine the filling volume, the system calculates the difference between the fuel level from this message and the message that precedes the start of the filling.

Calculate filling volume by raw data

This option can be useful if you set a high level of median filtering for smoothing the outliers of FLS values. As a result of such filtering, the values of the initial and final fuel level and of the filling volume are distorted. Under certain conditions, the option allows replacing them with the values calculated on the basis of raw data, that is, the data before smoothing. The filling interval itself, though, is calculated on the basis of the smoothed data.

If this option is enabled, the system uses the following algorithm:

-

The filling volume (Vfilled) is calculated according to the formula:

Vfilled= Vmax— Vmin,

where:

Vmax is the maximum fuel level within the filling interval according to the raw data;

Vmin is the minimum fuel level within the filling interval according to the raw data.

Vmin is also considered to be the initial fuel level within the filling interval. To calculate the final level within this interval, the filling volume (Vfilled) is added to the initial level.

-

If the resulting value of the filling volume exceeds the volume calculated on the basis of raw data, the values of the initial and final level and of the filling volume are replaced with the new ones. Otherwise, the values remain the same.

Timeout to separate consecutive fillings

If this option is enabled and more than one filling within a short time interval is detected, the fillings are combined into one, provided that the time between them (timeout) does not exceed the time indicated in this setting.

In the fields for indicating duration value, you can enter only 0 or an integer greater than 0.

You can get information on fillings by executing the Fuel fillings report, using the Send fuel information by email or SMS job or the notification about fuel fillings.

Drain detection settings

Calculate drains by time

It is similar to the Calculate fillings by time option (see above).

Detect fuel drains in motion

This setting becomes available only after activating the previous option. The setting allows detecting drains not only during stops, but also during movement, which can be useful, for example, for ships. However, in many cases, activating this option can result in the detection of false drains due to changes in fuel level, for example, while driving on rough terrain.

Minimum stop duration to detect a fuel drain

This setting is available only if the Detect fuel drains in motion option is disabled. Here you can specify the minimum duration of the interval without movement which is followed by a decrease in the fuel level by more than the minimum fuel drain volume indicated in the basic settings.

Calculate drain volume by raw data

It is similar to the Calculate filling volume by raw data option (see above).

Timeout to separate consecutive drains

If this option is enabled and more than one drain during a short time interval is detected, the drains are combined into one, provided that the time between them (timeout) does not exceed the time indicated in this setting and the fuel level has not increased.

In the fields for indicating duration value, you can enter only 0 or an integer greater than 0.

You can get information on drains by executing the Fuel drains report, using the Send fuel information by email or SMS job or the notification about drains.

Questions and answers

Video: Gurtam | Training session. Fuel control

You can find information about fuel control in the following video dated 26.09.2019: